China Clean room construction solutions

We are a China one-stop service provider of clean room construction solutions suit for ISO 8 to ISO 5

We are a China one-stop service provider of clean room constructions solutions suit for ISO 8 to ISO 5 , including customized HEPA and ULPA air filters, clean clothes, electronic cleaning wipes, sterile wipes, Polyurethane (PU) sealants, Precision Appliance Cleaners, Oil stain remover etc.

ISO 5 cleanrooms

ISO 5 cleanrooms, also known as Class 100, are highly controlled environments designed to minimize airborne particulate matter, with a maximum of 100,000 particles 0.1 microns or larger per cubic meter. ISO 5 cleanrooms can be more expensive to build and operate due to stringent requirements for airflow, filtration, and maintenance.

Ceiling coverage:

ISO 5 cleanrooms typically have a high percentage of fan filter units (FFU) in their ceilings, ranging from 35% to 70%, to ensure adequate airflow and air exchange.

Air changes:

ISO 5 cleanrooms typically require a high number of air changes per hour, typically 240 to 360 HEPA filtered air changes per hour, and fewer than 29 particles greater than or equal to 5 microns per cubic meter.

Protective clothing procedures:

Strict clothing procedures must be in place to minimize personnel contamination, typically including coveralls, hoods, gloves, and boots.

ISO 5 cleanroom applications:

This type of cleanroom is often used in industries such as semiconductor manufacturing, pharmaceutical production, and medical device manufacturing.

ISO 6 cleanrooms

ISO 6 cleanrooms, also known as Class 1000 cleanrooms, are controlled environments designed to minimize airborne particles. They are characterized by a particle count of no more than 1 million per cubic meter and a particle size of no less than 0.1 micrometer. These cleanrooms are often used in industries that require precise control of contamination, such as medical device manufacturing, electronics, and pharmaceutical synthesis.

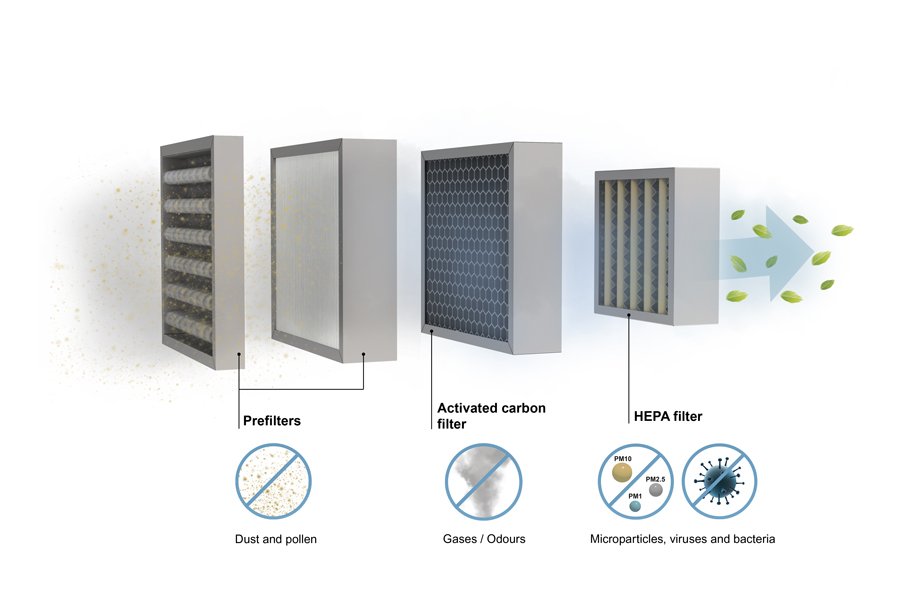

Filtration:

They typically employ HEPA (High Efficiency Particulate Air) or ULPA (Ultra Low Penetration Air) filters to remove airborne particles.

Air changes:

ISO 6 cleanrooms maintain a high number of air changes per hour, typically between 90 and 180.

Clothing requirements:

Personnel entering ISO 6 cleanrooms must wear specific protective clothing, including coveralls, hoods, shoe covers, and gloves.

Applications of ISO 6 cleanrooms:

Medical device manufacturing: Electronics manufacturing: Pharmaceutical formulation: Laboratories: Aerospace, cosmetics, and semiconductor manufacturing also use ISO 6 cleanrooms.

ISO 7 cleanrooms

ISO 7 cleanrooms, also known as Class 10,000 cleanrooms, are controlled environments where air quality is maintained to specific standards. A maximum of 10,000 particles (≥ 0.5 microns) per cubic meter is allowed. ISO Class 7 cleanrooms are commonly used in industries such as medical device manufacturing, electronics, and drug compounding.

Filtration:

ISO 7 cleanrooms use high-efficiency air filtration systems (usually HEPA or ULPA filters) to remove airborne particles.

Air Change Rate:

ISO 7 cleanrooms typically have 30-60 air changes per hour.

Protective Clothing and Airlocks:

Gowning rooms and airlocks are essential to maintain cleanliness and minimize contamination when entering and exiting the cleanroom.

ISO 7 Cleanroom Applications:

Medical Device Manufacturing: Electronics Manufacturing: Drug Compounding: Laboratories: Cosmetic Production:

ISO 8 cleanrooms

ISO 8 cleanrooms, also known as Class 100,000 cleanrooms, are controlled environments that limit the number and size of particles in the air. It allows for up to 3,520,000 particles of 0.5 microns or larger per cubic meter. While the controls in an ISO Class 8 cleanroom are less stringent than those in higher classes, it is suitable for a variety of applications that require a moderate level of cleanliness.

Filtration:

ISO 8 cleanrooms utilize a high-efficiency particulate air (HEPA) filtration system to remove particles from the air.

Air changes:

They typically require 10 to 25 air changes per hour.

Dress code:

Depending on the specific application and the cleanliness requirements within the cleanroom, the recommended dress code may include head covers, goggles, beard covers, lab coats, foot covers, and gloves.

ISO 8 cleanroom applications:

They are typically used in manufacturing processes, general production facilities, and some laboratory environments.