In the modern pharmaceutical industry, the choice between restrictive endoscopes (RABS) and isolators is one of the most critical decisions when designing a sterile process. Both systems can be designed to comply with GMP standards, and both are designed to minimize cross-contamination and protect the product.

As experts in controlled contaminated environments, Master understands that choosing between restrictive endoscopes (RABS) and isolators is more than just a matter of cost or availability. It requires an approach that blends science, experience, and a long-term perspective.

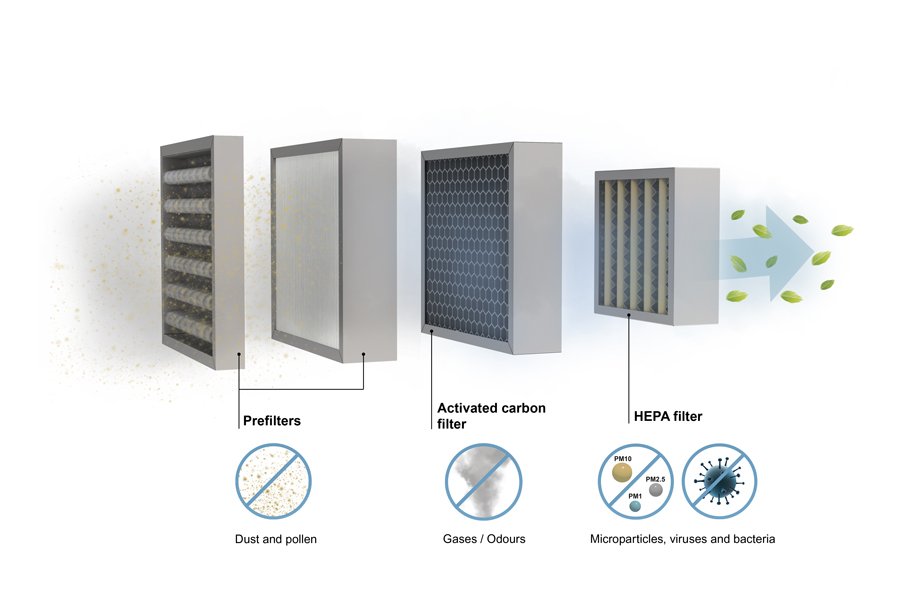

RABS (Restricted Access Barrier Systems) are physical barriers that restrict direct access to critical areas. They incorporate unidirectional airflow, positive pressure, HEPA filtration, and ergonomic glove port design.

In contrast, isolators are completely enclosed systems with HEPA/ULPA recirculating filtration, automated decontamination (e.g., VHP), differential pressure, and complete isolation between operator and product.

- RABS vs. Isolators: What Level of Containment Do You Need?

A key factor in the comparison of restricted area endoscopic (RABS) and isolators is assessing microbiological and toxicological risks. For example:

In filling lines for parenterals, vaccines, or active pharmaceutical ingredients (ATMPs), isolators can provide a fully enclosed environment with validated HEPA/ULPA decontamination cycles.

For smaller-scale or less sensitive production, RABS may be sufficient as long as strict procedures and well-trained personnel are in place.

- Flexibility and Repeatability: Another Key Factor

Production type can also influence the decision between RABS and isolators:

RABS offer greater flexibility. They are ideal for multi-product facilities with short production runs or frequent recipe changes.

Isolators excel in stable, repetitive processes. Once validated, they ensure consistent aseptic conditions for each batch.

Many facilities combine RABS and isolators: RABS for auxiliary areas or early stages, and isolators for final filling or packaging. For small-scale production, especially in facilities with existing Grade B cleanrooms, RABS can be a cost-effective solution. Isolators, on the other hand, can be installed in Grade C or D environments, providing greater flexibility for new area designs or space optimization.

- RABS vs. Isolators: Long-Term Economic Analysis

From an economic perspective, the RABS vs. isolator debate goes far beyond initial cost:

Confined space isolation systems (RABS) offer lower equipment costs and higher cleanroom investment. They also incur higher heating, ventilation, and air conditioning (HVAC) usage and require more consumables for cleaning, validation, and gowning.

Isolators offer greater stability and predictability, resulting in higher equipment costs and reduced cleanroom infrastructure requirements. Due to the lower room rating, energy consumption and consumables are lower, requiring ongoing performance monitoring.

Ultimately, the comparison between RABS and isolators isn’t just about technology; it’s also about risk management philosophies.

If your operations require rapid changeovers, RABS offer faster turnaround. However, for unbiased repeatability, isolators offer unparalleled structural advantages. Choosing the right system between RABS and isolators not only improves current performance but also shapes your ability to scale, certify, and automate processes in the future.

Are you evaluating RABS and isolators for a new facility, or looking to optimize an existing production line?

Contact our technical team and take the next step with confidence and clarity.