Fan-filter units (FFUs) are the unsung heroes of controlled environment like cleanrooms, providing vital air filtration and circulation to maintain the clean conditions required by a wide range of industries.

- FFU Purpose

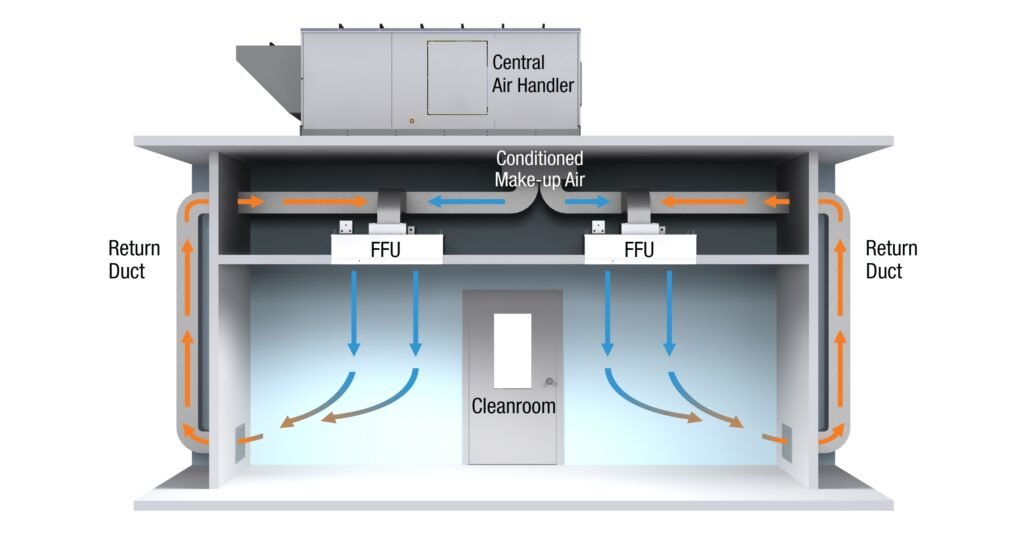

FFUs filter air to create or maintain a sterile environment within cleanrooms. Their primary function is to remove airborne contaminants, ensuring the air quality within controlled environments like cleanrooms is conducive to sensitive operations. FFUs are indispensable tools supporting industries such as pharmaceutical and electronics manufacturing.

- FFU Structure

FFUs consist of multiple components, including a fan, filters, and a housing unit. The fan drives air through the unit, while the filters, particularly HEPA filters, capture and remove contaminants.

- How FFUs Work

1. Fan Start: The process begins when the fan inside the FFU starts, drawing air in from the surrounding environment.

2. Initial Air Filter: Air first passes through a pre-filter, which captures larger particles, ensuring that only relatively clean air enters the FFU body.

3. Air enters the FFU enclosure: Within the enclosure, the air undergoes finer filtration and preparation.

4. HEPA filtration: Air passes through a HEPA filter, which captures 99.97% of airborne particles as small as 0.3 microns.

5. Clean air enters the cleanroom: The purified air is exhausted into the cleanroom, supporting a cleanliness-critical environment.

FFUs are crucial for maintaining air quality standards in controlled environment like cleanrooms, ensuring they meet international standards. This is crucial for both safety and productivity in high-risk environments.

We are a one-stop service provider of clean room consumables suit for ISO 8 to ISO 5 , including HEPA and ULPA air filters, clean clothes, electronic cleaning wipes, sterile wipes, Polyurethane (PU) sealants, Precision Appliance Cleaners, Oil stain remover

etc. Please contact us whenever you need them.