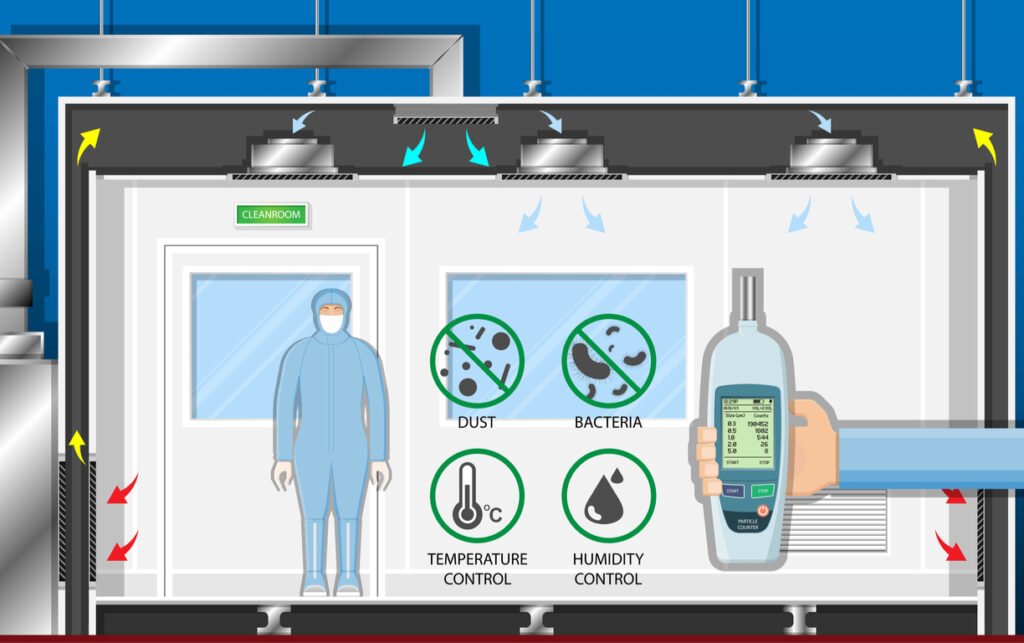

Clean rooms are key environments for controlling pollution and maintaining air quality, especially in high-precision fields such as semiconductors, pharmaceuticals, and food processing. The presence of dust not only affects production quality, but may also cause equipment failure and unqualified products. Therefore, clean room dust control is the basic work to ensure production safety and quality.

Sources of dust in clean rooms

Dust control in modular clean rooms, the sources of dust in clean rooms mainly include external air, internal personnel, equipment, raw materials, etc. External air is an important source of dust, especially in the absence of an effective filtration system. According to the ISO 14644-1 standard, the number of air particles in a clean room should be controlled to not exceed the specified value per cubic meter. For example, ISO level 7 requires that particles larger than 0.5 microns do not exceed 352,000.

1. External air pollution

Dust in the external air often enters the clean room through ventilation systems, doors and windows, etc. In order to avoid this pollution, clean rooms are usually equipped with high-efficiency air filtration systems, such as HEPA filter or ULPA air filter.

2. Personnel and equipment pollution

The staff and equipment in the clean room are also the main sources of dust. The staff’s clothing, skin and other materials may carry dust. Equipment may also generate tiny dust during operation, especially processing or cleaning equipment. The use of personal protective equipment such as dust-free clothing and gloves can effectively reduce this pollution.

3. Imported raw materials and products

When raw materials and products enter the clean room from the outside, they may bring in dust or particles. Therefore, controlling the inlet and outlet process and using clean packaging during transportation can effectively reduce the introduction of external pollutants.

Clean room dust control, air filtration system is an important means of clean room dust control. Efficient air filtration can not only remove most of the particles, but also ensure that the airflow direction, pressure, temperature and humidity in the clean room meet the standards.

1. HEPA and ULPA filters

HEPA filters can capture more than 99.97% of particles larger than 0.3 microns, while ULPA filters are more efficient and can capture 99.999% of particles. According to ISO 14644-1, the number and size of particles in the cleanroom air must be strictly controlled. For example, the number of particles larger than 0.5 microns in the air of an ISO 7 cleanroom should not exceed 3,520,000.

2. Air flow and pressure difference

The airflow organization design in the cleanroom should ensure continuous air circulation, prevent dead corners and airflow turbulence, and reduce dust accumulation. According to ISO 14644-4, a certain air pressure difference should be maintained in the cleanroom to ensure that air flows from the clean area to the contaminated area.

3. Air exchange rate and purification effect

The air exchange rate (number of air changes per hour, ACH) of the modular cleanroom is also an important factor affecting air quality. Efficient air circulation can remove particulate matter in the air in time. ISO 14644-4 recommends that areas with higher cleanliness (such as ISO 7) should reach 30-40 air exchanges per hour.

Cleaning and maintenance of cleanrooms

In addition to the control of the air filtration system, the cleaning and maintenance of cleanrooms are equally important for the control of cleanroom dust. Regular cleaning and maintenance can reduce dust accumulation and bacterial growth, ensuring a clean environment.

Cleanroom monitoring technology

Cleanroom dust control, the monitoring system in the cleanroom is the “eye” to ensure air quality. Real-time monitoring can help managers to find dust pollution sources in time and take measures quickly.

Cleanroom dust control is an important part of ensuring product quality and improving production efficiency. From air filtration to cleaning and maintenance, to monitoring and control, every detail is directly related to the working effect and production safety of the cleanroom. Through continuous optimization of technology, process and management, the dust control level of the cleanroom will continue to improve to meet the increasingly stringent industry requirements.